Achieving significant improvement in the throughput of sludge combined with minimising reactive maintenance and the frequent need to purchase spares, were the important benefits achieved at a key Southern Water site, thanks to the installation of Vaughan Chopper Pumps and mixing systems, supplied by P&M Pumps. The site, a key element in Southern Water’s sludge strategy, serves a sludge catchment of approx 600,000 people and uses Mesophilic digestion and a thermal drying plant which needs to operate on a 24/7 basis.

The key processes at the site are split into two main functions. For the waste water process the stages are primary settlement, biological treatment and final settlement, and for sludge recycling; digestion, gas recycling, drying, the drying granules are recycled to agriculture. Pumps play a key role in the smooth running of these processes and Southern Water were experiencing problems prior to the installation of the Vaughan ‘chopper’ pumps.

The site has three 2400m3 Mesophilic digesters which are fed 24 hours a day with raw sludge containing a dry solids content (D/S) of between 6 and 8%. The digesters are heated using spiral heat exchanges with a primary heat source of around 60°C. Pumps then re-circulate the sludge through the heat exchangers to maintain a constant heat within the digesters and this temperature must be maintained at 35°C ± 2°C to ensure HACCP compliance. The previously installed screw centrifugal pumps frequently failed due to their inability to handle the amount of rag and grit in the sludge.

In addition, seal failure was common with one pump needing to be replaced on average every 4 to 6 weeks. The rag also caused blockages within the heat exchangers which meant they needed to be cleaned weekly to remove trapped rag from within, leading to operational process issues eg; expensive maintenance required to maintain the required throughput of the site 24/7. For example, if the temperature on any digester dropped below the critical control point, this would inhibit digester feed, reducing the site throughput by as much as one third. The financial consequences were monthly costs on the pumps of around £2000 each, plus the labour costs for contractors and call out of Southern Water staff.

P&M Pumps were asked to look at a possible solution and the recommendation was to install a HF4P6 15 kW Vaughan Chopper Pump to ensure the required flow was maintained and which would be able to cope with the rag and grit within the system. The first pump was installed and the operators reported how quiet the Vaughan Chopper pump was in comparison to the other pumps. As part of the maintenance process, operators continued to open up the heat exchangers, although they found that the build-up of rag was almost zero. It was also found that the digester temperatures consistently stabilised and remained so thanks to the ability of the heat exchangers to transfer the heat more efficiently without blockages or pump failures. Consequently, heat exchanger operational maintenance now consists of an annual inspection and there are no issues with rag build-up within the units.

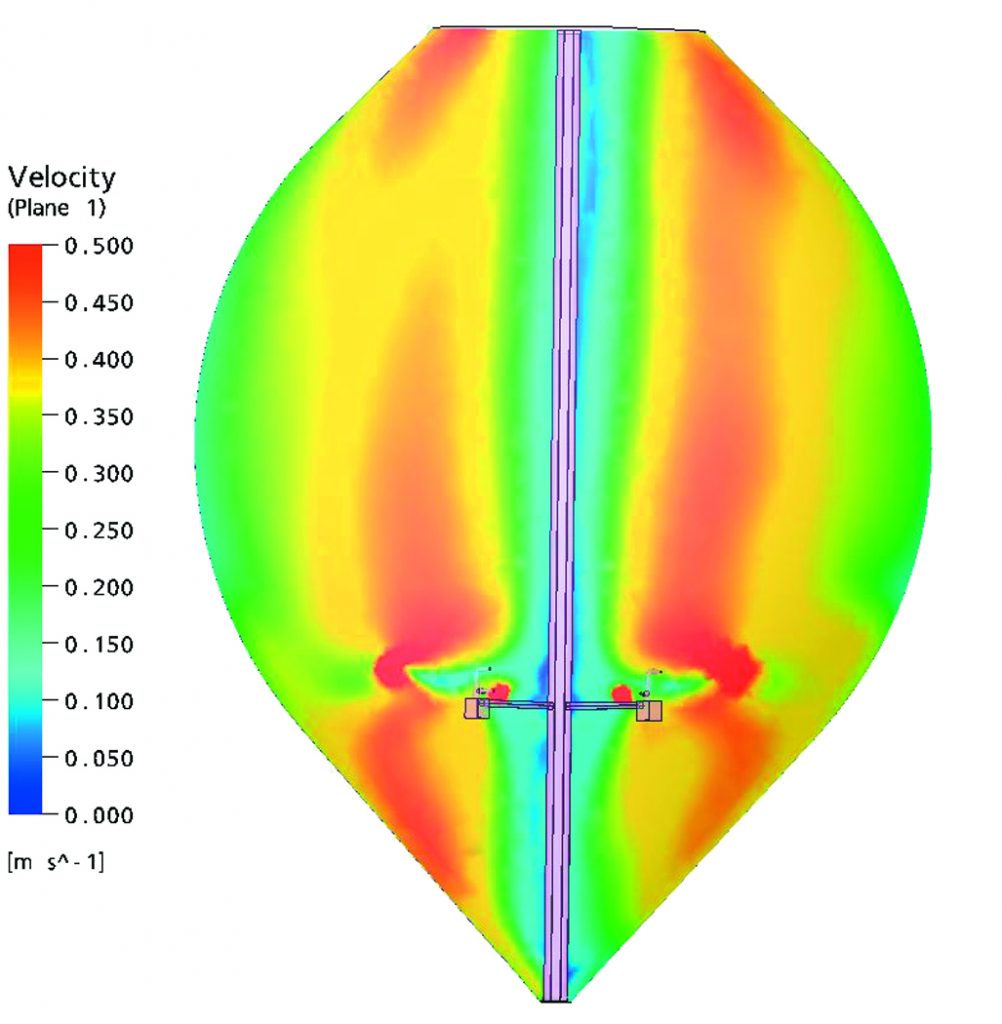

A further two pumps have subsequently been installed at the site and have been running for over 3 years with no reported blockages and minimal reactive maintenance. P&M Pumps, exclusive UK distributor for Vaughan Chopper Pumps, initially became involved with the Southern Water site in 2002 and to date have installed 8 pumps and 2 Rotamix systems.

Equipment includes 3 digester recirculation pumps, 2 post digestion storage tank Rotamix mixing systems, 2 belt thickener discharge pumps and 1 tanker discharge submersible pump.

Commenting on the performance of the Vaughan Chopper pumps, Mark Catlin, Southern Water Senior Process Engineer says, ‘Installing the Vaughan equipment has made a significant improvement to asset availability and a large reduction in this sites operational costs’. The conclusions underlined by the subsequent elimination of the downtime problems occurring at the Southern Water site are for operators to have a clear understanding of the potential operating costs when specifying equipment. Life costs are a significant factor in today’s increasingly regulated environment as are the incessant demands for improved efficiency. All these factors need to be factored into the initial specifying / buying process where comparisons of initial purchase price with probable on-going maintenance costs should be taken into account.

P&M Pumps, through their experiences at the Southern Water site and other installations, have been able to demonstrate that their products and expertise can bring significant cost-savings. In most cases, retrofitting Vaughan Chopper Pumps in the correct areas to deal effectively with the process, can be self-financing, with payback periods of less than one year, thereafter minimising the effect to the budget holders.

Further information on Vaughan Chopper Pumps and associated mixing systems is available from;

Matt Harvey, P&M Pumps Ltd, Sawtry, Huntingdon, UK.

Tel: +44 (0) 1487 830123

Fax: 01487 832888

Email: sales@thesolidsolution.co.uk

Website: www.pumpmix.co.uk